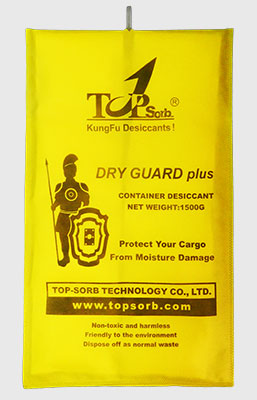

Dry Guard Bags-1500,1000,500g

Moisture damage

For many years, thousands of containerized cargoes are damaged by moisture problems. When the containers arrive in the destination, metal is found to be rusty or oxidated, cartons become soft and moldy, bulk coffee, cocoa, beans maybe damp, musty…,such loss sometimes costs several million dollars. It is caused by two main reasons:Cargo Sweat and Container Rain..

Container moisture solution

TOP-SORB focus on the supply of desiccant products and moisture-proof packaging system solutions and professional services, protect your valuable goods from humidity damage. For containerized cargo damp problems, we provide a solution, series container desiccants, TOP-SORBwhich create a dry environment in the container. It can effectively adsorb humidity, and control “dew point” temperature below the actual temperature, and thus prevent mildew, rust formation.

Dry Guard -1500g, 1000g, 500g

*Dry Guard Plus has double “breathing area”, which makes adsorption faster, more effective in the same space and period;

*Dry bag in small thickness, laminated non-woven, with hook, can be hung on the hoop;

*Reduce relative humidity, Control “dew point”, protect the cargo during the whole ocean voyage.

Show Pictures

Specification Sheet

| Specification | Pack Size (mm) |

Net Weight (g) |

Packing Qty(pcs/ctn) |

| Dry Guard Plus-1500 | 350*600 | 1500 | 4 |

| Dry Guard Plus-1000 | 350*450 | 1000 | 6 |

| Dry Guard Bag-500 | 250*330 | 500 | 20 |

Comparison Pictures

Before using Dry Guard After using Dry Guard

Usage instruction

1: Check whether the container is damaged, whether there is a hole or crack on the container wall, the top and bottom. Container doors can be closed tightly and the seal must be good.The container must be dry and clean before loading.

2: Inspection of container wood floor. if possible, do not use containers with wood floor humidity over 20%, it would increase the risk of damp.

3: Seal all air-vents on the container wall. Very important!

Desiccant plays an effective role only in a closed environment. If the container door is not shut tightly, or there is damage on the container or the air-vents inside are not sealed, desiccant will never be able to absorb up the moisture that continually enters from outside.

4. Hang Dry Guard and recommended dosage:Open the package and hang dry guard 1000 up to the iron hoop on the container wall,as shown in the picture,Use 6kg per 20’ container,12kg per 40’ container.For professional advice of desiccant dosage,please contact Topsorb.

Specification

Specification:1500g &1000g & 500g

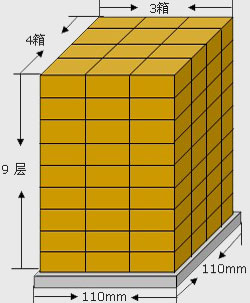

Carton Size: 370X275X220mm ;

Package:1pcs/1 PE bag,

1 big PE bag/carton;

Shelf life:24 months

Gross Weight:7kg;

Ctn Qty per pallet: 12ctns/layerX9 layer=108ctns

- Package Picture

- Loading Drawing

German |

German | English

English

info@topsorb.com

info@topsorb.com sales_topsorb

sales_topsorb